Waterjet Cutting

What is waterjet cutting?

Waterjet cutting or profiling is the cutting of a material to a predetermined shape using a ultra high pressure (3,800 bar) "jet" of water forced through a sapphire nozzle,

Depending on the material, usually the water is mixed at the cutting head with a very hard abrasive grit (garnet) creating an "abrasivejet" this jet effectively wears away the subjected material leaving a virtually smooth edge in comparison with other methods of cutting.

What are the benefits?

An important benefit of the water jet is the ability to cut material without interfering with its inherent structure, as there is no "heat-affected zone" (HAZ). Minimizing the effects of heat allows metals to be cut without harming or changing intrinsic properties and as such there is no deformation caused.

Waterjet cutting has the flexibility to cut 0.01 millimeter-thin plastic films to 200 millimeter-thick titanium whilst maintaining superb accuracy and edge parallelism this flexibility is also reflected in the range of materials that can be cut a few of which are:-

- Titanium

- Plastic

- Stainless steel

- Wood

- Hardox

- Rubber

- Brass

- Carbon Fibre

- Copper

- Composites

- Granite

- Marble

- Glass

- Mild Steel

Edge finish

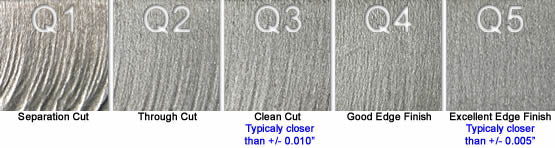

Taper and edge finish are directly related to cut speed. The greater the speed, the more taper and the coarser the edge finish. As the waterjet slows down, taper can be eliminated and the finish of about 120 achieved. Again, slower means an increase in time...and price

Tolerance

Our standard tolerance is +/-0.2mm.

Case Studies

-

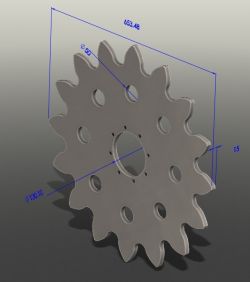

Bespoke Sprockets from...

"Westcountry Waterjet has recently profiled some bespoke sprockets from Hardox for a Sorcerer rotational...

View -

Copper Gaskets

Mr Price needed a copper gasket/spacer for a project he was working on, having no way...

View

Copyright ©2024 Westcountry Waterjet, Company No. 8945226, VAT No.186217983

Site design by Somerset Design