Waterjet vs Laser

The choice of whether to use waterjet or laser for your next cutting job depends entirely on what your specifications are. Because fixed tooling and fixturing are generally not required in Either cutting process set up costs are minimal for both. First question is what type of material do you want to use? What is the thickness? What sort of tolerance and edge finish are required for the job you’re doing. Will your part be effected by heat?

Edge Finish

The comparison below shows the edge finish on two alike mild steel blocks cut with both processes. Note the heat affected zone (HAZ) of the laser cut block this has not only changed the molecular structure of the material but also made the material hard in those ares making it more costly to machine. The waterjet cut block has no such HAZ therefore has no change to its molecular structure.

15x15x15 Mild steel block Laser cut

15x15x15 mild steel block waterjet cut

Material

While laser cutting can accommodate Non ferrous materials these are generally on the thinner side and with regard to plastics, wood and the like laser generates heat the edges will be burnt.

Waterjet on the other hand will cut ALL materials except toughened glass and diamond up to 200mm thick.

Thickness

While Laser is good up to 25mm waterjet can cut 200mm thick.

ACCURACY

Holes smaller in diameter than the thickness of the material can not be lasered however holes this small can be waterjet cut. Material flatness may be another point of interest in that thin materials may be warped by the laser proccess but waterjet can cut materials as thin as 0.001" with no issues.

Cost

Laser cutting of thin parts is no doubt the cheapest option however as the thickness increases waterjet becomes more and more cost effective.

Case Studies

-

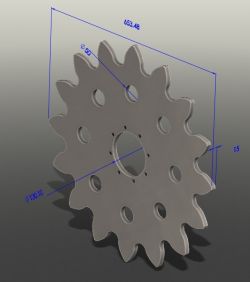

Bespoke Sprockets from...

"Westcountry Waterjet has recently profiled some bespoke sprockets from Hardox for a Sorcerer rotational...

View -

Copper Gaskets

Mr Price needed a copper gasket/spacer for a project he was working on, having no way...

View

Copyright ©2024 Westcountry Waterjet, Company No. 8945226, VAT No.186217983

Site design by Somerset Design